Military-Grade Quality Control: Likon Sports Redefining Precision

Recently, Likon Sports Leveraging cutting-edge quality assurance protocols, the company implements an eight-stage digital inspection system to guarantee dimensional accuracy within ±0.1mm. Advanced metallographic microscopes conduct microstructure analysis with 0.5μm resolution, while 100% of products undergo rigorous 72-hour salt spray corrosion testing (ASTM B117) and 3,000-hour QUV ultraviolet aging simulations—ensuring decades of maintenance-free service even in extreme environments.

Triple Core Innovations Revolutionizing Performance

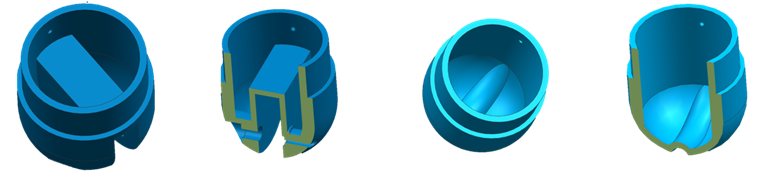

Intelligent Lightweight Architecture

1,The patented hollow-structure design reduces component weight by 35% while enhancing load-bearing capacity through optimized stress distribution.

2,Thread Reinforcement Technology

Proprietary groove patterning increases thread engagement depth by 50%, delivering unparalleled structural stability under dynamic loads.

3,Premium Transmission System

Integrated high-precision bearings and corrosion-resistant rollers enable seamless cable movement, reducing operational friction by 40%.

“This isn’t just product evolution—it’s a paradigm shift,” stated, Engineering director of Likon Sports. “By merging aerospace-grade material science with intelligent manufacturing, we’re empowering sports facilities worldwide to achieve unprecedented cost-efficiency and longevity.”

The new-generation tennis post caps are now available for global orders, with customized engineering solutions tailored to specific climate conditions and usage scenarios.